Join the

21st Century

Standard

Transforming electrode technology to unlock

green hydrogen and decarbonise industry

Our SPARKFUSE™ process sets the next industry standard for electrodes.

Because catalysis is core to decarbonisation, yet operates on last century tech.

Transformative

Our SPARKFUZE™ electrode coating process is transformative. It is more durable (10 years+), more energy efficient, as well as low cost. Yet it is easy to integrate, using your existing compounds.

Jolt’s technology shows a marked improvement in both electrode performance and durability… Their method is quick and easy to scale making them a fantastic partner for the future

Matteo Dragoni – COO, HyDEP srl

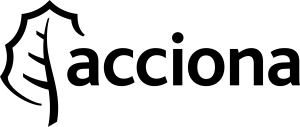

Rapid, large scale production

Our research centre in Barcelona is capable of manufacturing tens of thousands of m2, prototyping new customer electrodes for deployment close to their production sites.

Find out more

Why trust us

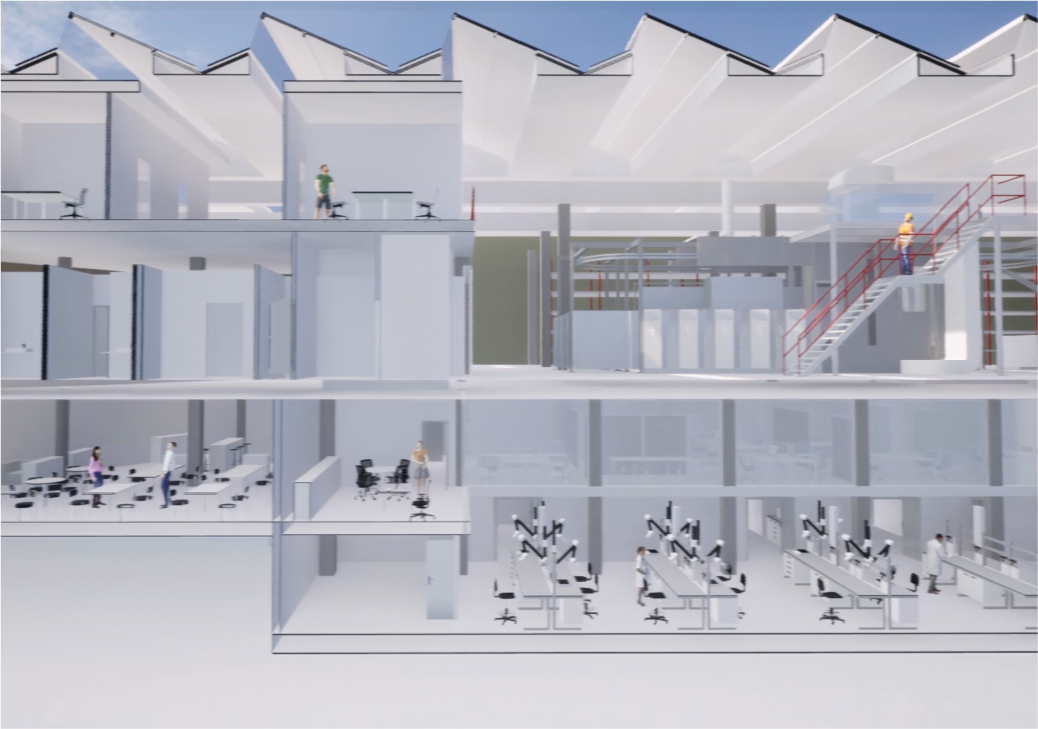

Jolt Solutions is the largest spinoff of ICIQ, a prestigious global research institute ranked amongst the world’s top 5, and one of the few focused on catalysis.

Sparkfuze™ has already been deployed in commercial stacks for alkaline electrolyers (AWE) and Anion Exchange Membrane (AEM) electrolysers and used to produce electrodes up to 3m in diameter.

Jolt stands ready to accept large scale production orders now for delivery with short lead times.

We are proud of our partners: public bodies and government,

leading Climate funds and global companies.

Organise a test

Let us demonstrate the efficiency and performance of the SPARKFUZE™ process.

Get in Touch

It may appear that the whole of catalytic technology is relatively mature. This is, however, a misconception because history teaches us that fields which appear mature are suddenly revitalized by a major discovery

H. Heinemann (1913 -2005), scientist and leader in the field of industrial catalysis